|

Le Moulin de Gô

Ruth Andrews

Pictures by Mick Watson

|

|

|

Just

before Christmas, ex-pat Mick Watson emailed HMG to

ask if we would be interested to hear about the

restoration of his derelict old watermill. Of

course, we said yes.

The

mill is at St Pierre-sur-Erve in Mayenne near Laval,

and is not to be confused with Le Moulin du Got, at

St Léonard de Noblat in Haute-Vienne near Limoges,

which HMG visited in 1998. This article is the

result, based on the information he has sent.

Mick

is a ‘builder by trade’ and he bought the mill some

25 years ago, along with several other properties,

but was unsure how to tackle the restoration.

|

|

However, in 2012 he was approached by a local

villager Jean-Claude Portiers who said his family

and friends wanted to volunteer to help renovate the

mill as a local heritage project. They said that

the stretch of river here is 70km long and at one

time it had 70 mills on it but now there are only

five left and this is the only one that isn’t

renovated. Mick said: “I just couldn’t see why they

would want to do it for nothing. People don’t

really normally work like that. That was the Friday

and they started work the following Tuesday. They

just turned up and started clearing overgrown plants

away. I’ve never seen anything like it. They

worked as if they were being paid.” (He’s

obviously never met the Heavy Gang!)

|

|

The mill is just outside St

Pierre-sur-Erve and was probably rebuilt between

1844 and 1847 on a site which dates back to at least

1772 and probably to the 14th century. Since this

rebuild it does not seem to have undergone any

important modifications, but it had not been used

since the late 1960s, and was in considerable

disrepair.

Aerial view by Eric Medard

|

.jpg) |

|

|

|

A

description of the mill on its website (as

translated by Google!) states:

“The

mill takes place on a derivation of the Erve. On

the ground floor, the poquerie contains the mill's

transmission mechanism, with the pit wheel, the

idler gear, and a large gear wheel that drove the

axes of the three wheels. Above, the floor's floor

joist is supported by cast iron columns resting on a

stone chest, delimiting a quadrangular space. A

wooden staircase provides access to the attic which

still houses two pairs of millstones out of three,

protected by wooden chests,

archings.”

|

|

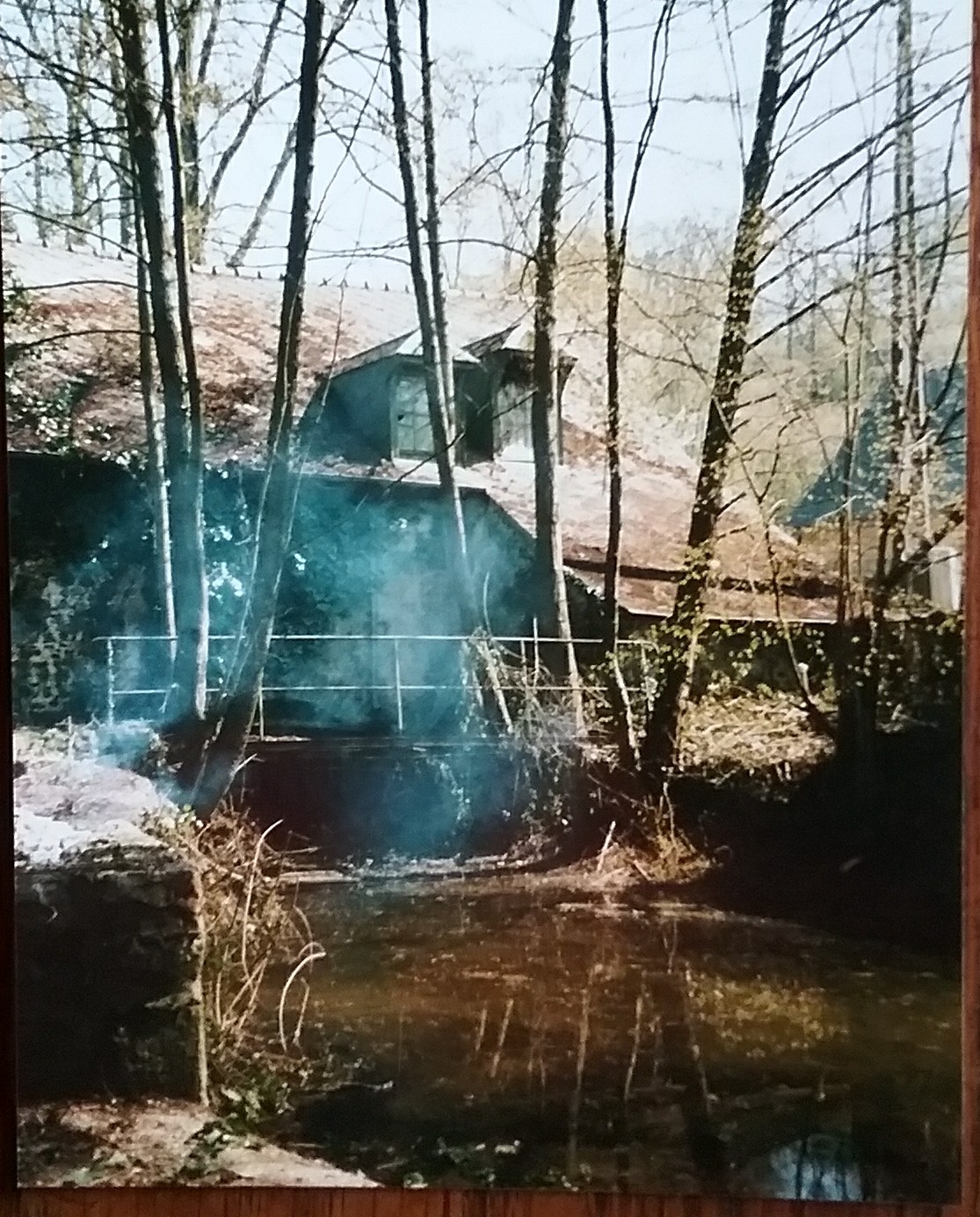

Restoration work began in 2012 and as nothing had

been done for over 20 years chain saws were needed

to even approach the building, and the tree roots

growing out of the walls had done a lot of damage.

As Mick says .”I needed to rebuild a lot of walls”.

Within a month the sluice gates leading from the

main river were open and the mill had water flowing

through it once again.

At

about this time the non-profit making association

Les Amis du Moulin de Gô was formed to restore,

maintain, and administer the mill.

Compare this picture with the restored building

at the start of the article.

|

|

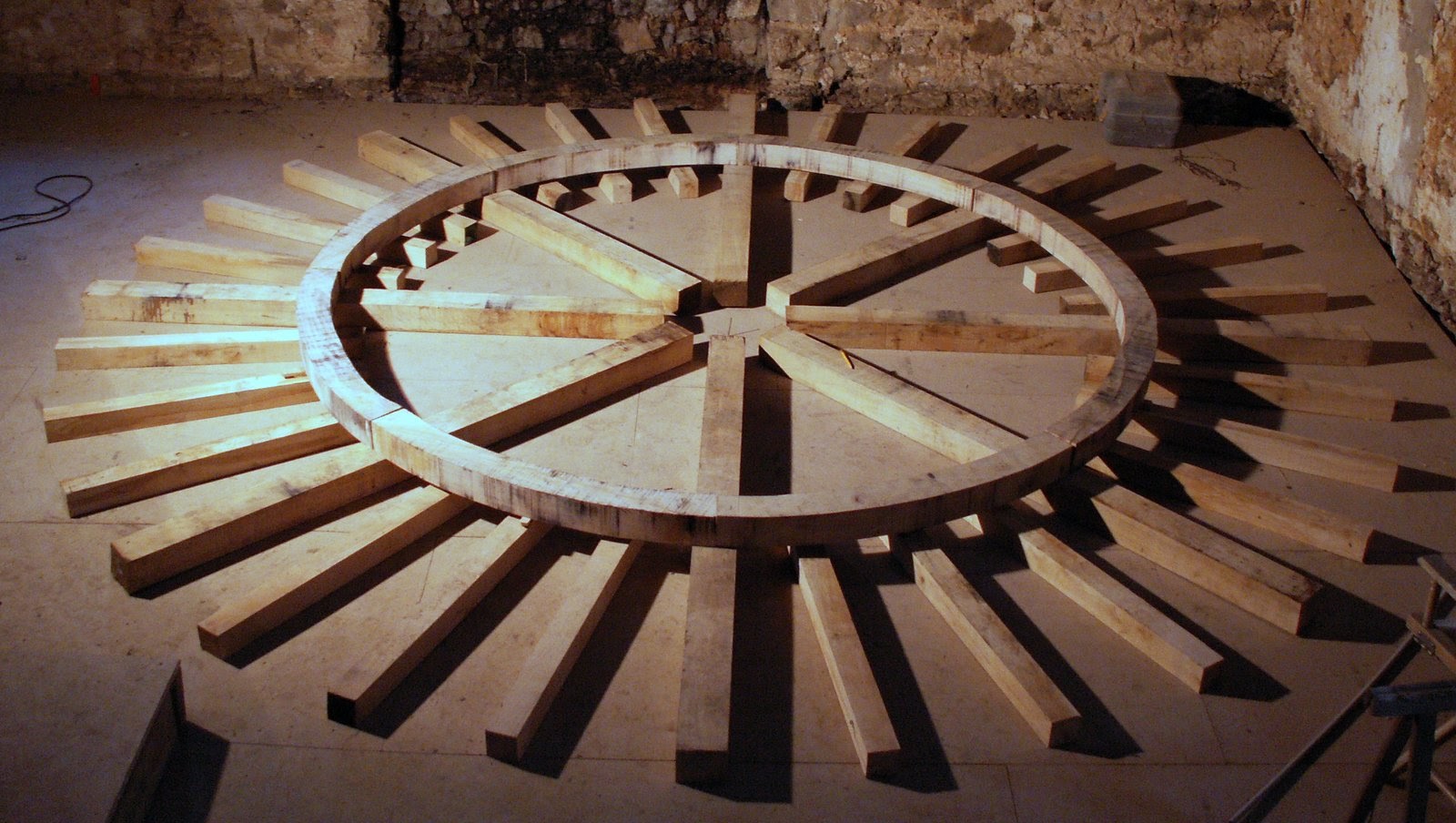

Late in 2013 a completely new waterwheel was

constructed using green oak; this was finished by

2014.

|

|

|

After the wheel, the volunteers tackled the

millstream, which needed dredging. It was over 400m

long and in places the silt and vegetation had built

up to over a metre deep. “After lowering the

barrage on the river and letting out the water,

Jean-Claude got in with the digger.” Whilst

clearing the millstream two World war 2 pistols and

ammunition were found: locals think that these were

hidden under an old bridge by the Resistance.

|

|

|

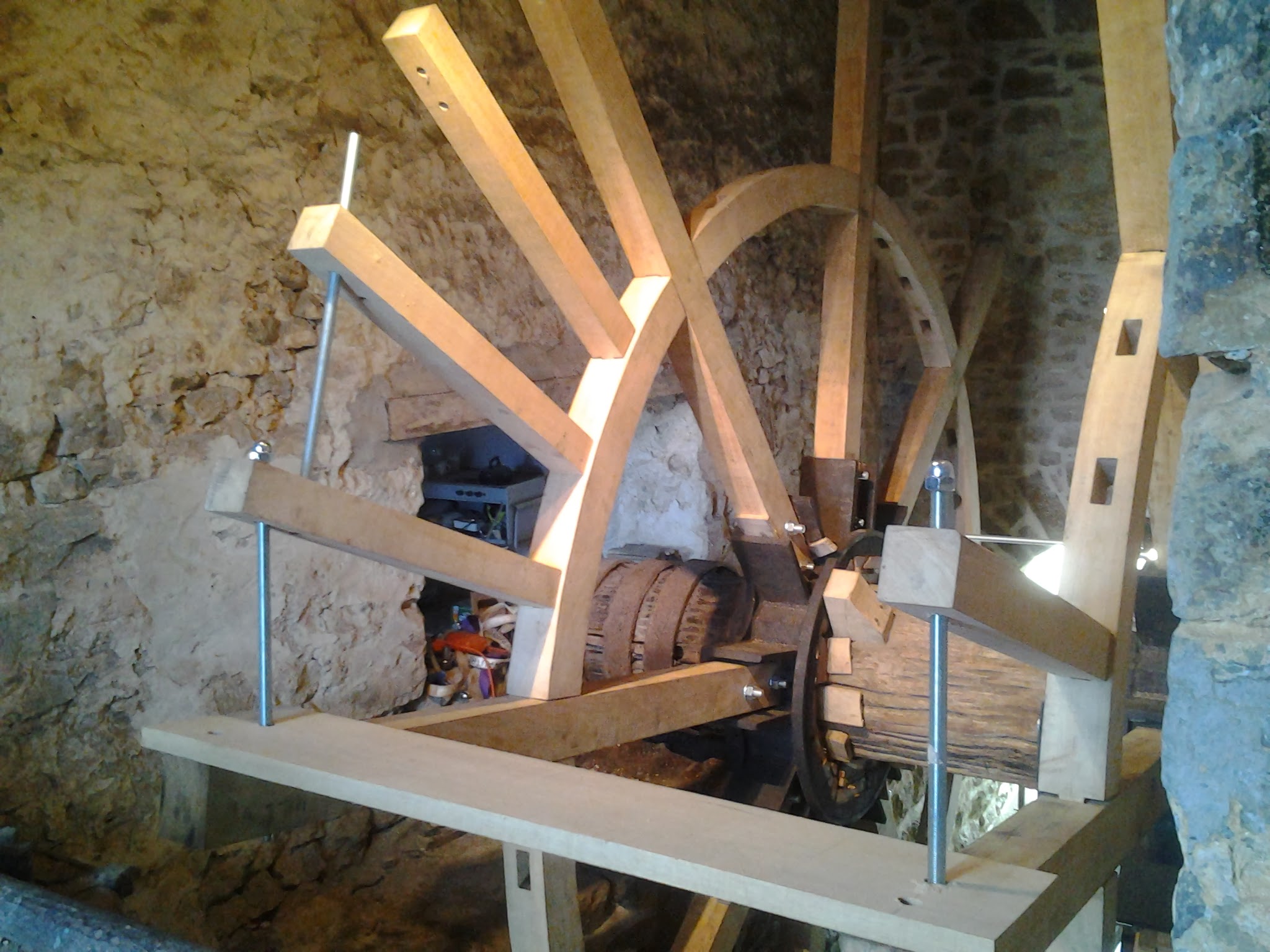

The next job was to sort out the drive mechanism.

The rotten teeth on the metal pit wheel and crown

wheel were replaced using acacia on the main drive

wheel and cormier (Sorbus domestica, service tree)

on the smaller gears. Cormier is

very difficult to find, but luckily a furniture

maker

in Mick’s local village had some, and made 250 teeth

which were fitted by Jean-Claude.

The first flour was produced in 2015. A local baker

used the flour to make a loaf of bread. However, it

may be a while before the mill can produce flour for

the public. “We’ll have to find out the legislation

with regard to producing flour for sale before we

can start grinding regularly,” Mick says. “We need

to ensure it’s fit for public consumption. In the

meantime, we grind flour on open days and people can

have a look at how it all works.”

|

|

Since

then Mick has also restored a 300-year old bread

oven located in a large room at the back of the

mill, which he hopes to use to produce bread and

pizzas from the mill’s flour.

At the end of 2018 the mill won a heritage prize for

the renovation work so far from an organization

called Sites et Monuments, which covers the whole

of France

Mick says: “For any of your members on Facebook I

set up a group called Watermill Enthusiast; if they

can find it they are more than welcome to join. Or

if you want to contact me or pay a visit to the mill

my email is

mickwatson8@gmail.com

.”

|

|

Compiled from information and articles supplied by

Mick:

Graft and Grind

by

Gillian Harvey in

Living France

(April

2016),

Keen locals bring mill back to life

by

Samantha David in

Connexion France

(https://www.connexionfrance.com/Archive/Keen-locals-bring-mill-back-to-life),

Moulin de Gô

at Saint Pierre de Erve

by

Susan Keefe in

The Good Life France

(https://www.thegoodlifefrance.com/moulin-de-go-saint-pierre-de-erve/),

The

Moulin de Gô

website

www.moulindego.com,

where you can

find more information.

|

|

|

|

When I

first saw the picture in this article of the

poquerie (repeated,

above left) I immediately thought of Soberton

mill, which –as reported in Newsletter 120 – has a

very unusual curved wall round the space which the

pit wheel, wallower, and great spur wheel would have

occupied (above

right).

The gears are long gone, but the stone spindle

bearings are still in place on top of the wall to

give a clue to the function of the structure. The

prominent pulleys are part of the belt drive from

the more recent turbine.

|