|

A chondrometer is a steelyard used to determine the

weight of a bushel of grain, using only a small

sample. ‘Chondro-‘ is said to be derived from the

Latinised form of Greek khondros meaning grain,

hence a chondrometer is a grain measure.

|

|

Chondrometers were developed in response to the ‘Act

for Ascertaining and Establishing Uniformity of

Weights & Measures’ of 17 June 1824, which came into

force on 1 January 1826. The act, in part, served

to define the Imperial gallon as the standard unit

of volume for liquids and dry goods. With regards

to trading dry goods such as wheat, barley, and oats

the bushel (equal to 8 Imperial

gallons) became the standard unit for buying and

selling purposes. As the quality (density and size)

of cereals can vary, then also the weight for a

given volume can vary. The chondrometer was

developed in order to calculate the weight per

bushel (bushel weight) from a small sample. This

allowed a trader (or miller) to gauge the quality of

the cereal.

|

|

|

Bushel weight (alternatively referred to as specific

weight or test weight per volume) is a function of

packing efficiency (the percentage of the bulk

volume occupied by the grain) and grain density.

The value is influenced by shrivelled grains, grain

shape, and surface characteristics such as brush

hairs, and surface condition which can be rough or

smooth. A high bushel weight indicates large dense

grains with lots of endosperm in them, which is good

for producing white flour. A low bushel weight

would indicate small thin even shrivelled grains,

with lots of corresponding surface area of bran and

low amounts of endosperm. This would not be ideal

for white flour extraction. |

|

Grain moisture and bushel weight are related in that

as moisture decreases, test weight increases. One

reason why test weight increases as the grain dries

is that dry grain packs together more easily than

wet grains. Additionally, as moisture decreases,

the grains shrink and this allows for more grains to

fill a volume.

Events that may occur during the grain-filling

period of the plant growth will influence the test

weight. Factors that decrease the rate or duration

of grain fill can result in lower test weights at

harvest. Included among these factors are excessive

soil moisture, lack of sunlight, drought, frost,

hail, temperature extremes, nutrient deficiencies,

and insect damage to leaf and stem tissue.

Bushel weight is normally determined after

mechanical cleaning of the wheat has taken place.

Originally in the UK its value was expressed

in pounds

per bushel (lbs/bu), but now more normally

in kilograms per hectolitre (kg/hl).

(1 hl = 100 litres). The

bushel weight for UK wheat is usually in the

range of 74 to 85 kg/hl (NABIM). |

|

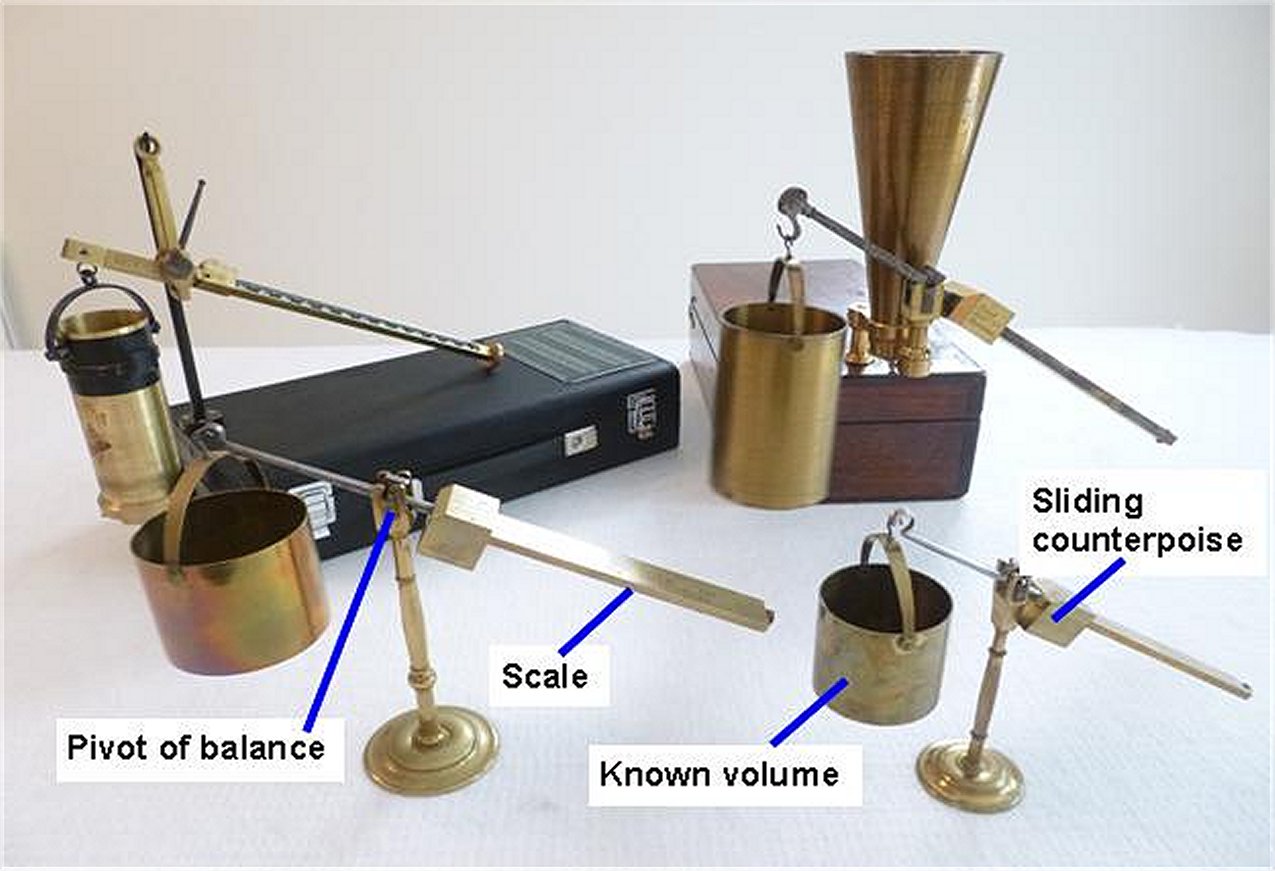

To use the chondrometer (as shown) the value is

obtained by pouring a sample of wheat into the known

volume, which is then levelled off with a wooden

‘strickle’ to remove the excess grain from the top.

This is achieved using zigzag motions of the

strickle. |

|

|

The volume is carefully placed on a scale and the

counterpoise is slid along the scale until balance

is achieved. The test weight is then read off the

scale, which is calibrated in ‘lbs per bushel’. |

|

Later chondrometers have an additional charging

volume (conical or cylindrical in shape) used to

provide uniform packing by filling in a controlled

manner. This is achieved either by opening a valve

or by use of a ‘cutter’. The cutter is a metal

blade (which also replaces the strickle) that can be

slid through the column of grain to isolate the

known volume. The process is shown below.

The known volume can then be weighed as in the

previous manner using the steelyard or nowadays by

using digital scales and converting the weight to

kg/hl with

a conversion chart.

|

|

|

|

1.Zero (tare) the known volume on digital scales |

2. Insert the cutter bar |

3. Place the charging volume on top |

4. Fill the charging volume with the grain |

|

|

|

5. Remove the cutter bar to allow the grain to fall

into the known volume |

6. Replace the cutter bar and remove the charging

cylinder |

|

8. Remove the cutter bar and weigh the grain-filled

volume |