|

In December we spet

a couple of days in the Peak District visiting our

son. We had realised that the weather would be poor

(we just missed the snows of storm Bett!) so we

decided to go to Macclesfield and visit the Silk

Museum.

Macclesfield

was once the world's largest producer of finished

silk, with 5000 looms and 71 mill factories.

|

|

Sheila Viner reported on her visit to Macclesfield

Silk Museum in

newsletter 120 (Spring 2018), but lamented that

the adjacent associated Paradise Mill was not open

that day. We

were able to book a guided tour of Paradise Mill,

which houses the jacquard hand looms as well as

visiting the free part of the museum, which is

housed in the former 1879 School of Arts building (right).

On entering the museum, we were slightly startled to

find a whole room full of Egyptian artefacts which

were donated by Marianne Brocklehurst and Mary

Booth, the two Victorian explorers who collected

them. We then progressed to several rooms full of a

wide range of textile (mostly silk) machines, which

are the ones that Sheila described. |

|

|

Here are a few more examples from the museum.

First, two mechanised Jacquard looms.

|

|

Below is the loom that wove the famous

Macclesfield silk pictures between 1936 and

1989. Each picture took a year to produce.

|

Above is a multi-shuttle 19th century ribbon loom.

When last in production it was making tags for Doc

Marten boots.

|

|

|

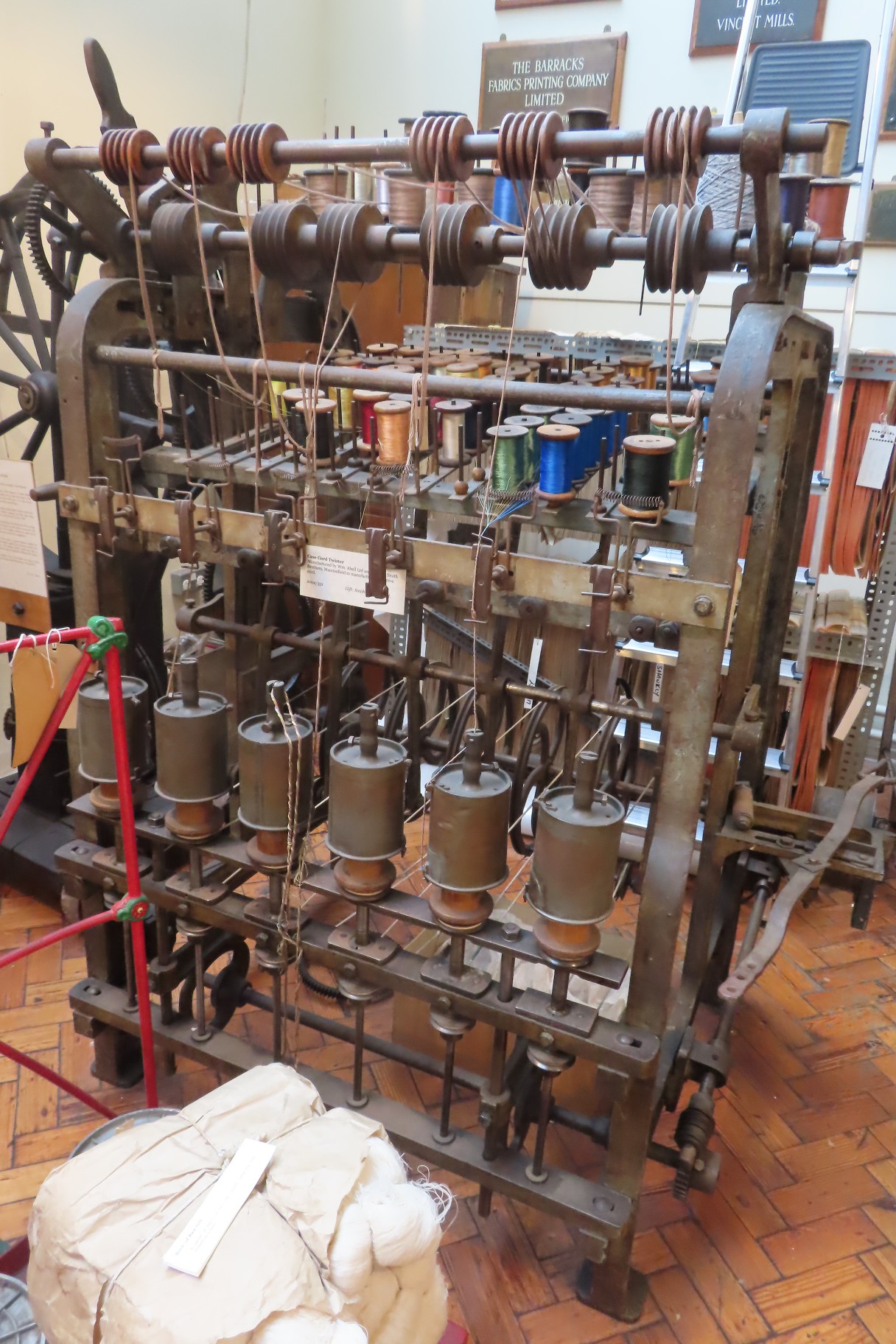

This is a case cord twister,

manufactured by Wm Abell Ltd, and used by Smith

Brothers, Macclesfield to manufacture decorative

cord.

Like most of the machines in the museum, it is set

up with threads so that you can see how it works.

In the foreground is a parcel of hanks of raw silk

weighing about 2kg, which is called a ’book’.

|

|

This throwing machine built around the 1830s

was used by Thomas Whittle in Leek until they closed

in 1995. It was used to add a twist to the yarn by

transferring the silk from one fast moving bobbin to

a slower one. This is not to be confused with

cotton or wool which need the twist to hold the

thread together, and is therefore spun, not thrown. |

|

|

We were very pleased to notice that almost all of

the machines in the museum were not only set up, but

had explanatory labels – in contrast to quite a lot

of other museums that we have visited.

|

|

|

At 11 o’clock we joined about 9 other people in the

foyer of the museum, and our expert and excellent

guide Daniel Hearn took us up the road to

Paradise Mill, and we climbed to the top floor

where the historic hand looms are situated. He took

us through the whole process of silk weaving, from

moth to cloth, before taking us round the weaving

floor. |

|

By 1912 a newly-established silk-weaving firm was

renting rooms in Paradise Mill. As the business

expanded they bought the mill and became

Cartwright & Sheldon who remained the owners and

principal occupants until the firm went into

liquidation in 1981. They decided to specialise in

high quality silk made by traditional labour

intensive methods using hand looms, some 70 being in

use in the 1930s. |

|

|

It is these looms, all dating from the 19th century,

that are on display in the mill today. Several are

being restored and are in use by technical college

students doing textile courses; there is also a

design centre. The mill has strong links with

Whitchurch Silk Mill.

Built in 1862, Paradise Mill is now the sole

survivor of Macclesfield’s industrial and creative

past. Itl has undergone

restoration with thanks to Allmand-Smith Ltd, who

own Lower Paradise Mill. This has been made

possible from a £309k National Heritage Memorial

Fund award, which allowed the Silk Heritage Trust,

who run the museum, to acquire a 125-year lease of

the top floor of Paradise Mill from owners Allmand-Smith

Ltd.

|

|

|

Looking over the viewing area rails, you can see the

warping machine which is in current use, complete

with white cloth to stop people walking though the

stretched out threads. |

|

Later in the tour we were able to walk down the

corridor between the two rows of looms. With hand

looms there is much less risk of a shuttle flying

out, so it is safe to be near them. Notice the

wooden construction and lack of drive belts.

|

|

|

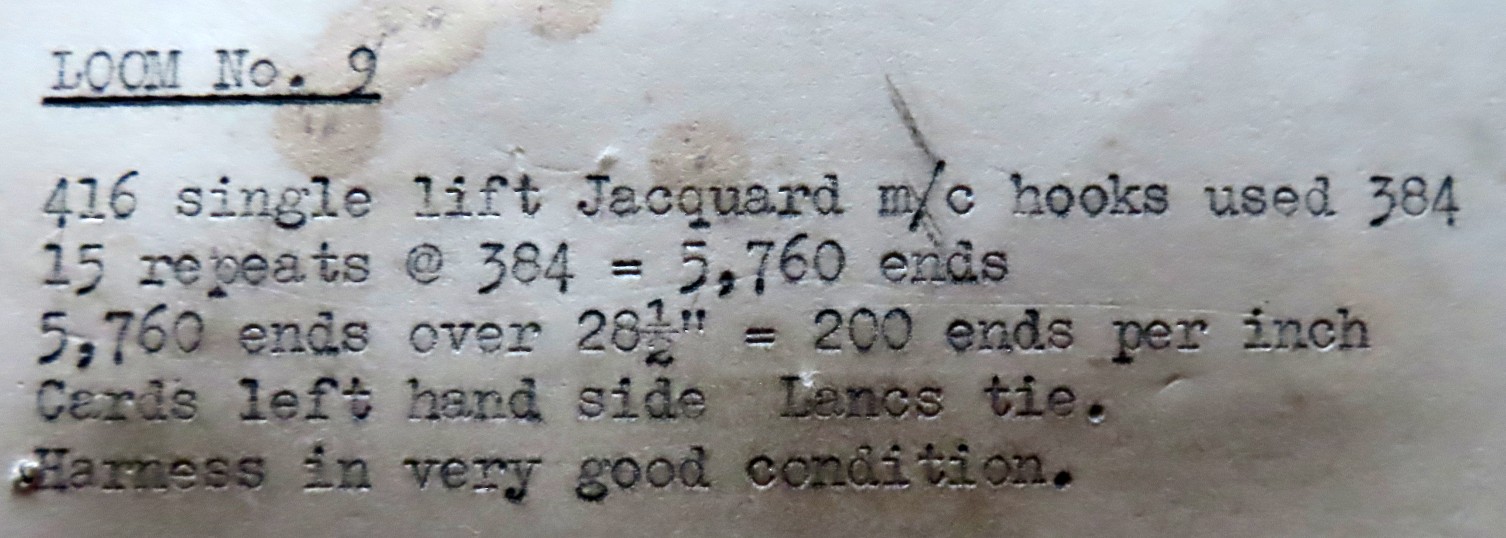

As you probably know, Jacquard looms rely on punched

cards to generate the pattern by controlling which

warp threads are lifted to allow the shuttle with

the weft to pass between them. Daniel demonstrated

the machine for cutting the cards, and explained how

the pattern is translated from the design drawing on

graph paper to holes in a sheet of card. On the

right is the Jacquard mechanism on top of a loom.

|

|

|

|

|

|

We were very lucky that one of the students had come

in to do some weaving, and she kindly talked us

through the process, including the difficulty of

maintaining a rhythm and operating the foot treadle

(necessitating standing up), and pulling the reed

forward to compact the cloth after each pass of the

shuttle. It is an extremely physically tiring

operation and the effort of pressing the treadle

down was said to be the equivalent of walking 15

miles in the day.

Information from the museum website

thesilkmuseum.co.uk,

their guide booklet,

and a booklet The Last Handloom Weavers ISBN

0904532062 published by Cheshire County Museums. |