|

|

|

Page 6 |

Newsletter 91, Winter 2010 © Hampshire Mills Group |

|

A Flax Mill in Romsey

by Jeff Hawksley |

|

Some little while ago Sheila, our

editor, wrote to ask about flax mills

and flax processing in the Hampshire

area. The answer is that there was a

flax mill in Romsey, two in

Fordingbridge and, no doubt, others too.

The mills in Fordingbridge were on a

larger scale and made sailcloth. Imagine

how much of this would have been needed

for the square-rigged sailing ships in

the 19th century.

The first mention of a flax mill in Romsey appears in The Hampshire

Chronicle of 4th November

1822 which carried a report of a young

girl called Fielder, aged 14 years, who

became entangled in the machinery and

died. A year later a Trade Directory

lists William Lintott, Flax Yarn

Spinners, Abbey Mills, Romsey. Tax

records show that Lintott already owned

the site in 1813 so it is possible, if

not probable, that he built and opened

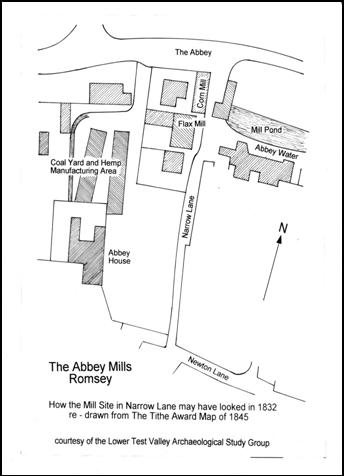

the mill shortly after. The sketch shows

how the area may have looked in 1832

with the flax mill at the end of Abbey

Water. Lintott lived in Abbey House and

the coal yard and hemp processing area

are also shown. |

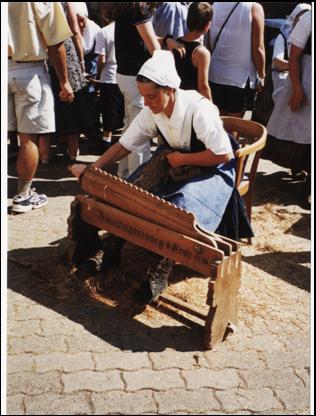

Flax

Breaker

photo by Jeff Hawksley |

|

Lintott kept the mill until he died in

1832 when it was advertised for sale as

“a superior water powered spinning

factory, three stories high with a new

bucket waterwheel 16 feet diameter”.

Today the head, or fall, of water at the

site is about 13 feet so, if this was

also the case in the 1830s, this

suggests the waterwheel would, most

likely, have been a high-breast wheel.

The advertisement includes “all those

two extensive and well built brick and

tiled buildings lately used by Messrs.

Lintott as stores and workshops for

manufacturing flax and hemp, with the

coal-yard adjoining”. In 1838 the

Parliamentary Return notes that the flax

mill at Romsey had a waterwheel of 16

horse-power and employed 31 persons,

over half of these being between the

ages of 13 and 18 years. In 1840 there

were 36 employees.

By 1843, maybe earlier, the mill had

been taken over by Samuel Thompson.

Thompson already owned the East Mills in

Fordingbridge which, in 1840, employed

200 hands. It was quite a substantial

business manufacturing ticking (a

striped linen or cotton cloth for

mattresses) and sailcloth. He also had

the West Mills in Fordingbridge in West

Street though at that time it was known

as Back Street

Back in Romsey, in 1842, a man was

prosecuted for stealing sacks from

Thompson's Mill which tells us that this

mill was also producing sacks. These

were important items at that time; all

the grain would have been brought to the

corn mills in sacks and sacks would have

been used again to carry the flour away.

It is clear that the Abbey Mill in

Romsey was spinning flax by machine in

1822 or earlier. At this time mechanical

spinning of flax was difficult and, up

to 1825, only the coarser grades of yarn

could be produced in this way. This

would not necessarily have been a

disadvantage in Romsey where, as we have

seen, sacking seems to have been the

primary product. |

|

It is also clear that the Romsey mill

was spinning hemp, which makes a rather

coarser yarn. Hemp and flax differ from

other textile fibres such as wool and

cotton in that several preparatory

processes are needed to separate the

useful fibres from the stems before

spinning can begin. And, whilst flax and

hemp come from different plant species,

the preparatory processes are very

similar for both. After the stalks have

been pulled from the ground, rather than

cut, the first step is to remove the

seeds. Later these may be crushed and

pressed to extract the linseed or hemp

seed oil. The stalks are dried and then

soaked in water to break down the woody

material which, later, has to be

separated from the useful fibres. This

soaking was done either by immersing

bundles of stalks in a pond or river,

called “retting”, or by spreading the

stalks on grass fields so that they are

wetted by the dew. Retting in ponds or

rivers polluted the water and,

apparently, smelled awful. |

After a suitable time the plants are

dried and subjected to further

processing to remove the woody outer

layers. There are three steps. First the

dried stalks were crushed in a “break”,

then bunches of fibres were beaten to

remove more of the woody material, a

process known as “scutching”. Finally

the fibres were drawn through a “hackle”

to align the fibres and remove any last

traces of woody material; a process

analogous to carding wool. The final

result, after all this work, is a

handful of lustrous silky strands of

flax.

Initially all these processes were

carried out by hand using simple wooden

tools built to traditional designs. The

three photos show a breaker, scutchers

and a hackle. On the Continent almost

any small country museum has examples of

breakers, scutchers and hackles on

display – they were an important in the

lives of country people. The photographs

were taken at a village fete in Germany

where the traditional tools and

materials appear to be readily to hand

and maidens in local costume have the

skills to demonstrate. Presumably the

same work was part of rural life in

England but neither equipment or

memories remain. This could be an

interesting area for further study. |

|

From about 1790 machines began to appear

to break, scutch and hackle the flax and

there is a considerable literature

available for Northern Ireland. But not

much for England. Nor has it yet been

possible to discover how much of the

preliminary processing was carried out

at the mill in Romsey or what was done

in the Hemp Manufacturing Area. The

census of 1851 for Romsey lists three

hemp dressers along with flax spinners,

weavers, sack makers etc.

With

so few dressers it seems likely the flax

or hemp was delivered ready for the

final combing but, so far, this is only

a guess.

|

Flax Hackle

photo by Jeff Hawksley |

|

In Fordingbridge, in 1853, there was an

exhibition at the Mechanic's Institute

where “Messrs. Thompson exhibited

specimens of their sail-cloth

manufacture, from its commencement in

the green flax to its completion”. From

this it would appear that they did all

the processing themselves but it is not

known whether the flax was grown locally

– another area for research perhaps ? |

|

What

happened to the Romsey Mill ? The flax

mill was still working in 1864 but by

1865 it appears to have changed hands.

By 1867 the corn mill had closed and by

1873 a new building had been erected on

the site which was used as a classroom.

This building is still there. Meanwhile

the flax mill had re-opened as a corn

mill. In 1892 the whole site was taken

over by the Sisters of La Sagesse, a

religious order of nuns from the Vendee

region of France and they are still

there.

Abbey House is home to the Sisters and

Saint Joseph's Church stands in the

place where Hemp was processed 150 years

ago. The corn mill continued until 1925

when it was destroyed by fire. It was

replaced in 1928 by a single-storey

building which also served as a

classroom. A glimpse of this building

can be seen today above the brick wall

at the end of Abbey Water; the dome at

the southern end surmounts a small

chapel. It is very difficult now to

visualise this peaceful corner of

Romsey as a busy industrial area but

that is what it was. |

Flax Scutchers

photo by Jeff

Hawksley |

|

|

|