|

|

|

Page 4 |

Newsletter 135 Winter 2021 © Hampshire Mills Group |

|

Farfield Mill, Sedbergh

Ruth Andrews

Photos by Ruth and Keith Andrews |

|

The

restoration of Farfield Mill is another successful

venture, but this time largely undertaken as a

community project by an army of determined

volunteers. Its restoration is the subject of an

extremely well-written and inspiring book written by

Maureen Lamb and published in 2008 entitled The

Story of Farfield Mill Restoration.

|

|

The first

mill at Farfield was built by Joseph Dover in 1837

for wool spinning and weaving. It is not of itself

much different from the hundreds of similar mills

which have not had such a determined band of

saviours. Before 1937 the mill was run by the Dover

family, but it was then sold.

|

|

Spinning

gradually declined, although it was also used for

storing wool and making cheese, as well as making

aircraft parts in the second world war. Between the

1960s and 1980s it had a revival when David Douglas

started weaving again under the name Pennine

Tweeds. He trained Bryan Hinton to use the

remaining Dobcross looms, and he subsequently took

over the business, but the end came in 1992 when he

gave it up. Soon after, a local resident visited

the mill to find Bryan about to dismantle the loom

for sale as scrap. A public meeting followed to see

if the mill could be saved, and the Sedbergh &

District Buildings Preservation Trust was formed.

Sedbergh in

Cumbria is the largest settlement within Yorkshire

Dales National Park but it is not a tourist

destination and its Dales Tourist Information Centre

had recorded fewer visitors than any other before it

closed in 2004. So the restoration of the mill was

an attempt to attract visitors and improve the

fortunes of the whole town. The project started in

1994 and the building was bought in 2000. It opened

to the public in 2001 as an arts, craft, and

heritage centre. That was the year of the foot and

mouth crisis; the local breed of sheep, Kendal

Rough Fell, were felt to be in danger of extinction

so the mill helped by buying about 1000 fleeces.

They set up a trust to provide post-graduate

weaver-designers with studios and the equipment to

weave a traditional heavy cloth called ‘ingrain’,

which it was hoped would become a high value niche

product.

When we

visited the mill post-Covid-19 it was just beginning

to recover from a forced period of stagnation. The

popular and successful café had not yet got back to

its full capacity and the entrance fee for the mill

was not being charged, but the shop was once again

in operation, and selling products made in the mill.

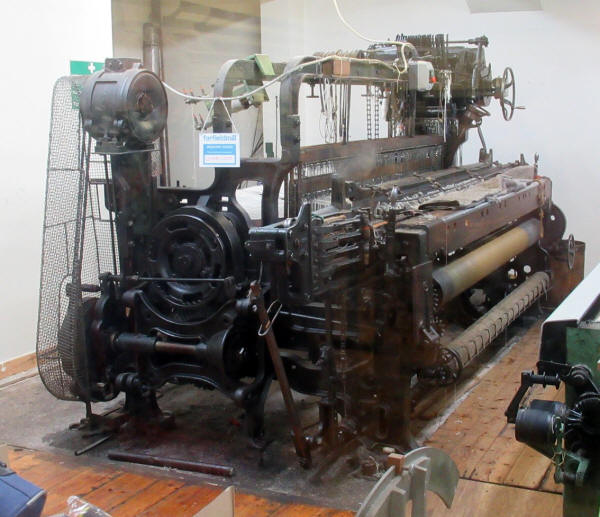

A separate

dustproof room houses the two automatic working

looms, one the 1936 Dobcross loom (above) made by

Hutchinson & Hollingworth of Diggle, Saddleworth,

the other an AC2 Somet loom from Italy bought in

2016 from a mill in the Scottish Borders, to work

alongside the Dobcross loom to speed up production.

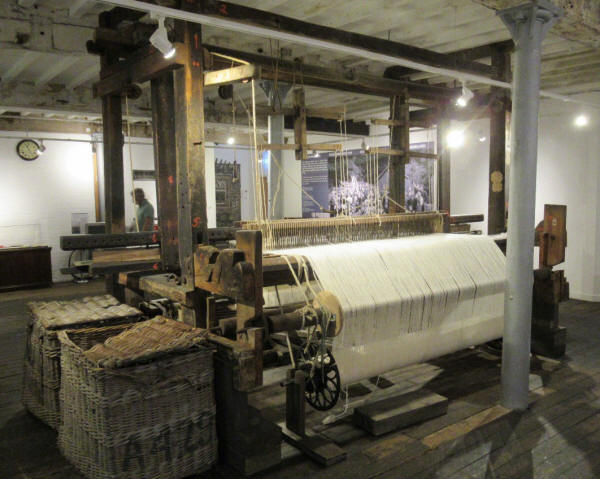

Also on display is a Witney blanket loom (below).

Standing over 9ft high, it is a timber framed 4

heddle hand loom dating from 1702; a flying shuttle

was added around 1800, so it is an important

survival.

|

|

Around the

mill, there are several different types of

hand-operated modern looms (right) in use in the

studios.

In addition

to the textile studios, there are workshops which

accommodate various other design and craft artists,

whose products are on sale in the mill and the town.

|

|

I didn’t

realise quite what a remarkable community effort had

been involved in the revival of the mill until I

read Maureen’s inspiring account of the hopes and

setbacks involved. It is a huge contrast to the way

that Gayle mill was funded and restored, and it

relies heavily on the mill earning its keep as a

working space, rather than just a museum.

Information from

www.farieldmill.org

and Maureen Lamb’s book. |

Finally I

should mention the Vortex turbine (left) with a fall

of 21ft, a suction of 14ft, and a rated power of

20hp (15Kw), supplied by Gilkes of Kendal in 1896,

which occupies the original wheelpit.

The whole

mill is built on a sloping site, so the front, seen

in the first picture, and the back (below) look very

different. The lower picture is an unrestored

warehouse on the site, which is awaiting reuse.

|

|

|