|

|

|

Page 7 |

Newsletter 126 Autumn 2019 © Hampshire Mills Group |

|

Siabost Norse Mill and Drying Kiln, Isle of Lewis

Ivor New

|

|

In early May my brother and I set off on a tour of

the Islands and Highlands of Scotland. It was the

week after the famous spring heatwave and there was

a complete reversal in the weather. When the sun

was out it was glorious; unfortunately the amount

of full sun was at least equalled by the rain, hail,

sleet and snow, the remaining time being overcast.

Not the best of weather when you are travelling in

a camper. We did not get down-hearted, just

accepted the walking we intended to do would be

curtailed and we would just have to spend more time

at tourist attractions and sampling the fare

provided by the local hostelries. |

|

We found the Norse Mill at Siabost (Shawbost) by

following the brown tourist road sign. The location

of the mill is dictated by the course of the nearby

stream which flows out of Loch Roinavat. This is

not unusual as many similar mills were built on

streams fed by lochs and it is easy to find ruins in

this sort of location that could well have been

mills. |

|

|

These mills provide an insight into the life of the

poor on Lewis and other small communities in the

Highlands and Islands. Historically these

communities had attributes that can well be

described as feudal and life was hard. Early on

there were clearances forcibly imposed on the

Jacobite supporting communities for political

reasons but later the pressures were economic. In

common with other poorer areas in Europe the very

existence of this type of community became

problematical as the social pressures produced by

the Industrial Revolution became more intense and

landowners increasingly found their tenants were

unable to generate income, causing the established

way of living to become untenable.

At other times differing pressures provided the main

catalyst for the depopulation, the two most

significant immediate causes being famine and

unemployment. The Irish potato famine is well

recognised but the potato blight, fed by a decade of

poor harvests, spread over the poorer areas of

Scotland and much of mainland Europe. The results

were the same – starvation and emigration. The

Industrial Revolution also led to depopulation of

the countryside and the improvements in hygiene led

to an increase in population with no proportional

increase in income to support it, which only

increased hardship.

The reactions of the land-owners varied from blatant

disregard for their ex-tenants to providing them

with some support. We found two examples of

landlords that actively followed the latter path.

In one case tenants were provided with passage to

Canada to join established Scottish communities

where free land was available. (I’m not trying to

justify colonialism, just acknowledging the

provision of a new life for impoverished people.)

In the other case the landowner built a new harbour

for fishing boats with associated housing, thus

making available food and income for the surviving

population.

In general, the net result was that countless

small communities were lost, although some managed

to survive well into the 20th century. These were

in the minority and most such hamlets have

completely disappeared from sight, becoming

indistinguishable and overgrown in the landscape. There

were hundreds of grain mills scattered throughout

Lewis by the 1840s that were used to mill corn or

barley. The Siabost mill and its drying kiln were

still in use until the 1930s although they are now

the only visible buildings on the hillside.

Restoration of the mill and kiln was started in the

1960s, however the buildings as they stand now were

completed in 1995, although they have been

rethatched recently. The interiors of both

buildings are quite dark as there are no windows.

The two oval buildings have rubble dry stone double

skinned walls and have well-constructed traditional

thatched roofs which are roped down about twin

crowsticks. This can be seen in the pictures.

|

|

The design of this and many of the mills around

Lewis is ancient and date back to the Vikings or

possibly even the Iron Age.

Editor:

There is a set of 4 such mills at Valtos on Lewis

(my guide book says). I have seen other examples in

Orkney and Shetland, and also in Bosnia and

Montenegro (the last as described in

my article above).

They are also in the Faroe Islands, which I plan to

write about in the next newsletter.

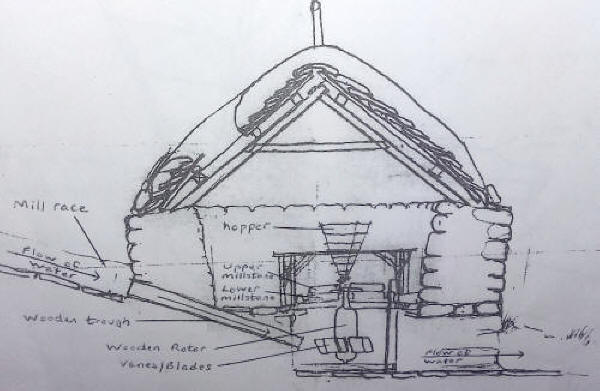

Grain is fed from the hopper to a spout attached to

it which is vibrated by the clapper peg which runs

on the uneven surface of the running stone and so

feeds grain into the throat of the upper stone at a

rate proportional to the speed of rotation of the

stone. The grain then proceeds between the stones

and appears as meal at the periphery of the bed

stone and falls into a channel from which it is

swept into a waiting bag or basket.

|

|

|

Water from the loch is channelled to the top of the

mill race just behind the mill. Here the land

slopes downward to the mill where the fast-flowing

water is used to turn the millstone. In the mill

undercroft the water drives a vertical shaft with a

set of paddles (tirl) beneath the mill floor which

directly drives the running stone. This is visible

through the gap in the undercroft wall that

accommodates the tail race. The tentering mechanism

can also be seen which comprises a simple lever

arrangement that raises the whole of the vertical

paddle shaft and running stone, so adjusting the

separation of the stones and hence the fineness of

the meal produced.

|

|

|

|

|

|

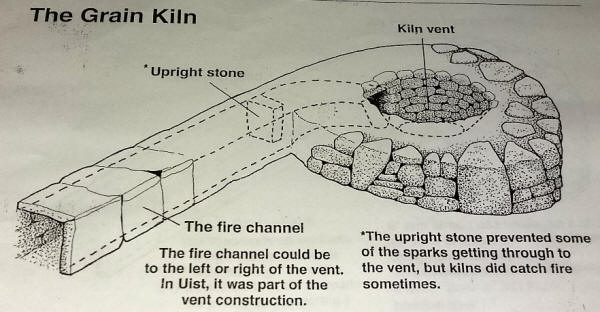

It is not obvious from

the diagram how the kiln operates. Externally there

is a channel which presumably provides fresh air for

the fire and drying process, something like a Roman

hypocaust. Inside there is a round stone-lined pit

which is connected to the outside channel. |

|

|

Clearly the grain would

be laid out to be dried in the building, although it

is not clear how this would have been arranged in

detail, but nonetheless the grain must have been

dried adequately to be milled effectively.

Editor: I suspect that there was some sort of

platform supported on the ledge above the bowl of

the kiln. This ledge is visible in the photograph,

but not in the diagram. |

|

|