|

|

|

Page 7 |

Newsletter 125 Summer 2019 © Hampshire Mills Group |

|

Bere Mill, Whitchurch

Ivor New

Photos by Eleanor Yates

|

|

The Bere Mill complex of buildings was largely burnt

down in a major fire just over a year ago. The

house was badly damaged with the roof, its interior,

and much of the exterior walling being destroyed.

The mill and barn fared even worse with essentially

everything except heavy metal, foundations, and some

walling being consumed by the fire. The house has

now been rebuilt and restored to a high standard, so

attention has turned to the renovation of the mill.

Rupert and Elizabeth Nabarro, the mill owners,

invited a team from HMG to visit the mill to discuss

the possible options available before they start

this work

The mill proper is set over the River Test upstream

of Whitchurch. It has been used for various tasks

over its life but in the early years of the 20th

century it was converted into an electrical power

generating station to provide power to the

Laverstoke papermill which is about a mile away via

the direct footpath, and a little further via the

river.

|

|

|

|

A Gilkes turbine with automatic sluice control was

installed to drive a 440V generator. The power from

this was fed to the paper mill via a cable described

as coaxial, which was later sold to supply power to

St Michaels Mount. As it was clearly a submersible

cable one can but speculate that it could have been

laid on the river bed for speed and cheapness of

installation and ease of removal.

After the second world war the turbine was

refurbished and the generator rewound to provide 40A

at 220V DC, nominally 8.8kW, but in practice

probably providing a maximum of about 7.5kW. |

|

|

The power generated, being at half the earlier

voltage, would have been much safer, and in addition

to supplying Laverstoke power was also made

available locally. This change would mean that the

supply cable would need twice the current rating to

supply the same power so the original one was

replaced. This configuration remained intact and

was operated, at least intermittently, to provide

power on site until it was destroyed by the fire.

When we arrived, Rupert welcomed us and described

the general state of the buildings. He then took us

to view the remains of the mill.

|

Generator (above), meters and

electrical distribution equipment (on right). |

|

|

It was a sad sight with virtually nothing remaining

except the stabilised foundations with the

vertically mounted turbine in situ together with the

burnt-out metal work of the drive gearing, turbine

controls, generator, meters and electrical

distribution equipment. All the auxiliary

equipment, with the possible exception of the bevel

gear at the top of the turbine shaft, is almost

certainly beyond economic repair.

|

|

The cast iron bevel gear, while only in the order of

a metre in diameter and comprising a rim with

mortices to locate the wooden cogs and six heavy

flanged spokes, in all weighs in the order of ¼-½

ton. The expansion caused by the intense heat has

caused stress cracking or breaking associated with

each of the six segments of the wheel.

The most obvious issues are: a compound break in

the circumference; two broken spokes; and two

segments with hairline cracks in the circumference.

Even with all this damage the wheel is all in one

piece so it is understood that a specialist company

may be able to repair it, but it might be simpler to

use the broken wheel as a pattern to cast a new one. |

|

|

The later years of the 19th and early years of the

20th century were important in the development of

power generation and transmission. It was over

these years that the principles of electricity

generation and effective distribution as a utility

became understood. The mill’s unusual and

historically important configuration which was

installed at this time makes it a prime candidate

for conservation as even in its current state it

provides a good insight into an unusual example of

the technology of the time.

Assuming the mill owners accept this, it would seem

there are three basic routes that could be followed:

1. Stabilise and conserve the equipment of this

historically important system into a ‘museum’

exhibit.

2. Repair, refurbish, and source replacement

equipment, as required, to rebuild the generation

equipment and generation capability to that which

was lost, the aim being to maintain the historical

integrity of the site.

3. Undertake basic conservation as in option 1

(but accepting some detailed changes may be needed

for this option to work) and then install a modern

generating capability with the new turbine being

installed in the headrace just upstream of the old

one. The installation should be designed to

minimise changes to the existing environment,

although some changes to the hatches and around the

old turbine would probably be necessary. It is

anticipated that any new generating system would be

fitted with modern electronic controls that would

allow power generated in manual mode to be used

locally, and power generated in auto mode to be fed

into the grid.

Clearly any work done must fit in with long term

plans for the mill and will have its own attributes

and costs. The mill owners will clearly have an

unenviable task as they try to balance the cost

benefit equation that will inevitably have to be

resolved. |

|

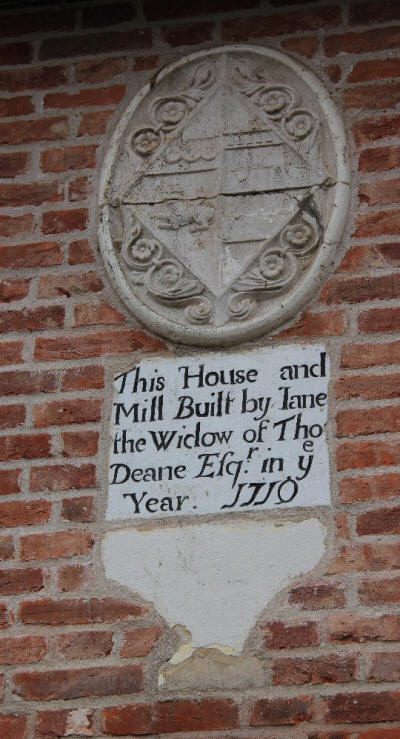

On a historical note, all the well-known information

regarding the mill has it springing into life when

the mill house was built in 1711. It does seem

surprising that this clearly viable location had not

been used previously as a mill site. When looking

at the 25,000 Ordnance Survey map while writing this

a surprising detail was noticed – Bere Mill is

written in antique lettering, which means at some

stage the mapping survey thought the mill was a

‘non-Roman site of antiquity’. It would be

interesting to see if this is the case.

Finally, we would like to thank Rupert and Elizabeth

for their hospitality and the opportunity to see the

mill in its current sad state, and hope our visit

was useful. We wish them well in their endeavours

to bring the mill back to a useful form that will

enable it to survive well into the future. |

|

|

Planning Applications have been lodged with

Basingstoke & Deane Borough Council for repairs to

Bere Mill.

The Basingstoke Gazette of 18 May 2019

reports

here. |

|

|