|

|

|

Page 6 |

Newsletter 124 Spring 2019 © Hampshire Mills Group |

Closure of a Traditional Maltings

Robin Appel

Pictures by Andy Fish

|

|

Tuckers Maltings

at Newton Abbott, Devon, closed at the end of

October. |

|

This was one of only 4 traditional ‘floor’ maltings

still operating in England and Wales, the others are

at Warminster, Wiltshire, Great Ryburgh, Norfolk,

and Castleford in Yorkshire. In Scotland there are

eight more ‘floor’ maltings, each one part of their

own distillery, but only one of these, Springbank,

makes all its own malt, the others just make enough

to maintain the craft, and satisfy the tourist

industry. It would be fair to say that traditional

‘floor’ maltings are more rare than working

windmills and water mills.

Edwin Tucker started a seed business in Ashburton,

Devon, in 1831. The company quickly expanded into

malt production with many tiny malt houses dotted

across the West Country, before consolidating into

one large malthouse at Ashburton in 1870, which

remained open for the next 100 years. |

|

|

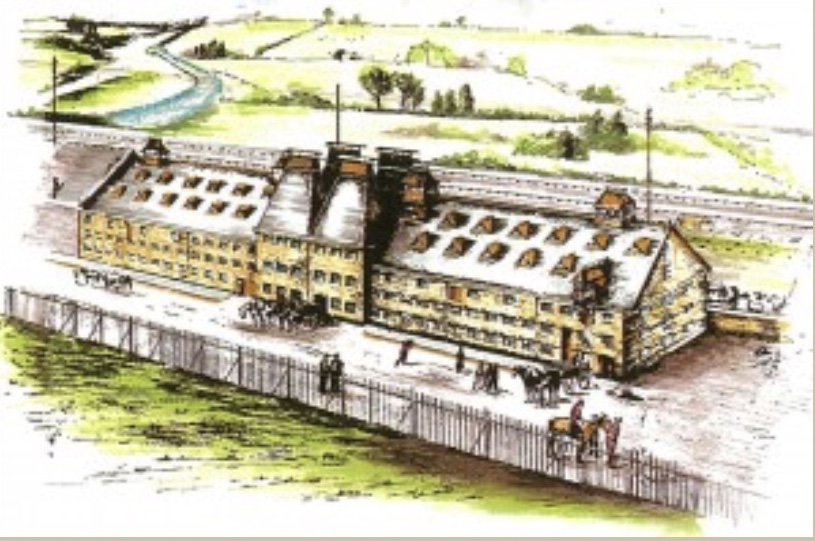

At the end of the 19th century, Edwin’s son, Parnell

Tucker, seized the opportunity to build an even

larger new maltings alongside the railway line at

Newton Abbott. Designed by the well known maltings

and brewery architect and engineer, William

Bradford, the first phase of the construction, with

two germination floors and two kilns, was completed

in November 1900.

Architects drawing of the new maltings |

With a capacity of 60 quarters (12 imperial tons) of

barley per batch, this was always known as the “big

side”.

The second phase of construction, with three

germination floors and two more kilns was completed

in 1901, with a capacity of 50 quarters (10 imperial

tons) of barley per batch, and known as the “small

side". |

|

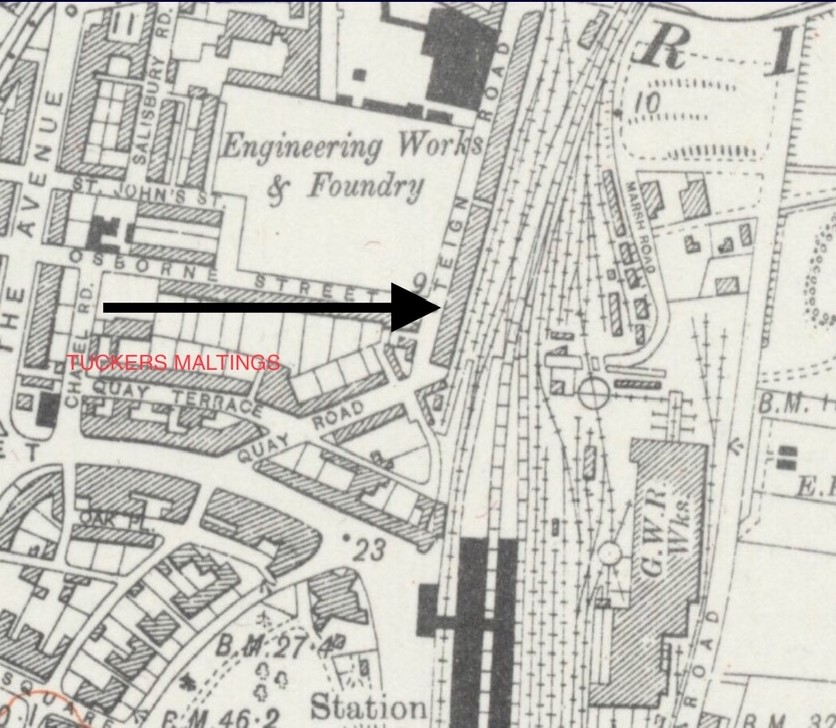

The structure of the maltings was a north-south

configuration, with a public road (Teign Road)

running along the western elevation, off which

deliveries of barley in sacks could be loaded into

the malthouses, and a railway siding ran along the

eastern elevation, onto which deliveries of malt

could be loaded out. The design of the building was

eventually replicated, south, all along Teign Road.

After World War 2 Tuckers acquired a large part of

this for a granary for both barley storage,and

cereal and other agricultural seeds. Today part of

this space is the Teignworthy Brewery, which until

the end of October, boasted the shortest (malt)

supply line of any brewery in the country!

|

|

The 4 original coal fired kilns, which took at least

three days to dry and cure the malt, were replaced

with oil fired technology in the 1960’s – safer and

half the time – but only two of the kilns were

converted, and the other two were deconstructed. |

|

Sadly, Parnell Tucker, and his immediate successors,

could never have foreseen the day when sacks of

barley would be replaced by deliveries in bulk

aboard huge lorries, requiring a whole new

logistical and engineering solution. At the same

time, a housing development to the north of the

maltings, converted Teign Road into a busy

thoroughfare. Then the demise of the railway as the

preferred transport for delivering the malt added

another logistical challenge. All of these features

represented a major drawback to developing and

expanding the business. |

|

|

Right up to the end, the maltings continued to

employ a whole raft of vintage equipment, including

hand pulled malt ploughs, hand operated ‘Redler’

malt turners, and ‘Robert Boby’ malt barrows, all of

which would be up to 70 years old. None of this is

unusual for traditional ‘floor’ maltings. However,

until recently, Tuckers still operated a 1900

vintage ‘Nalder and Nalder’ barley screen, along

with its twin malt screen. The original invoice on

the wall showed that the pair were purchased for the

princely sum of £203 0s 0d.

Since the millennium, exponential growth in the

number of Craft Breweries, offered Tuckers a new

lease of life, feeding an almost frenzied demand for

Craft Ale from the tourists flocking onto the

south-west peninsular. But, eventually, the big

malt factories from the eastern counties, with their

huge economies of scale, came barging in with offers

of cheap malt, stealing Tucker’s customers away from

underneath their noses. With no apparent

inclination to fight back, and no succession plan,

the business was inevitably, and sadly, doomed!

Now, Warminster Maltings in Wiltshire, Britain’s

oldest working, and most original ‘floor’ maltings

(1855), stands completely on its own in the West

Country. |

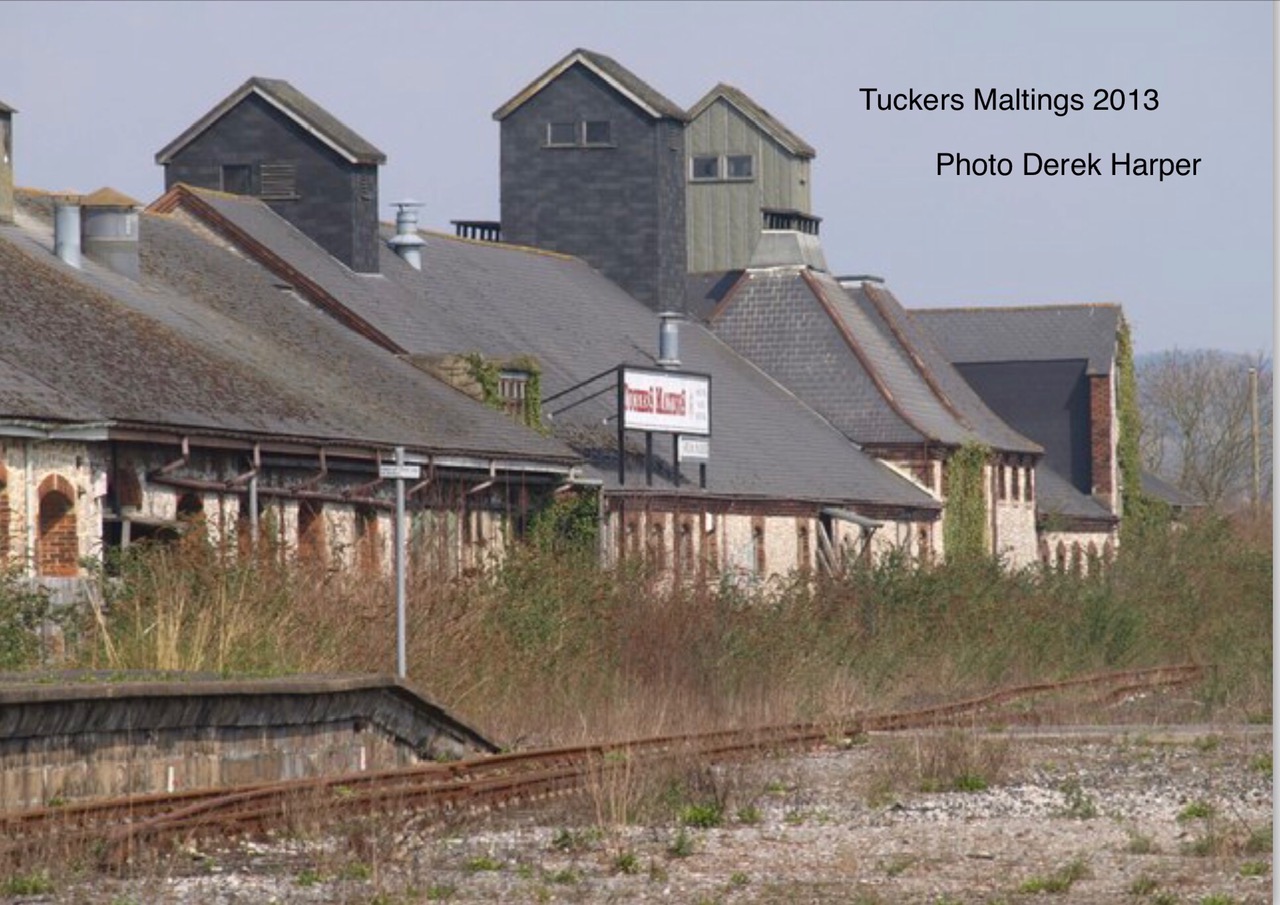

View along Teign Road, looking away from the river.

Note the interesting discharge shoot, with chain,

just beyond the ‘For Sale’ sign. |

|

|

|