|

|

|

Page 2 |

Newsletter 123, WInter 2018 © Hampshire Mills Group |

Eling - The Experience, and Tide Mill Maltings

Alison Stott,

Robin Appel

|

|

Eling - The Experience, by Alison Stott

Following our Annual General Meeting on 14 September

we had a talk by Ruth Kerr, one of the members of

the Eling Experience team. The Eling Experience

project encompasses the Tide Mill, the Heritage

Centre, and Bartley Water. Totton and Eling Council

run the site and the New Forest District Council own

the Tide Mill.

Ruth began by asking how many members had experience

of applying for a Heritage Lottery grant (hardly

any!). She explained that HLF have their own

objectives and if yours have nothing in common with

theirs then it will not work. Their main aims are

‘Heritage’, ‘People’, and ‘Communities’.

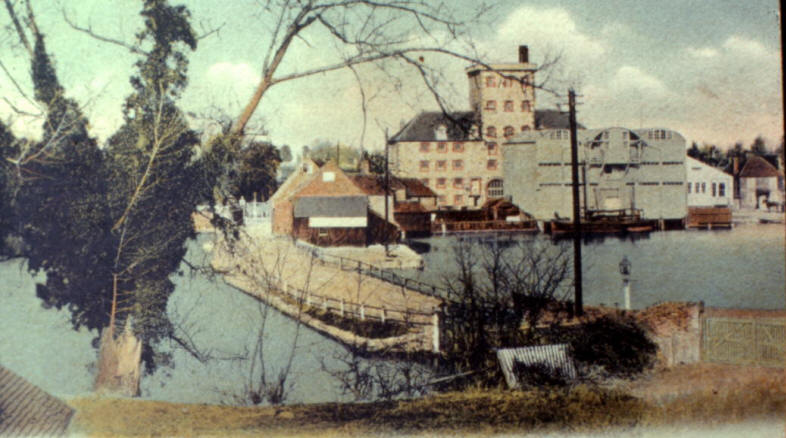

Copy of FGO Stewart postcard, about 1900, which

shows the tide mill and its causeway,

and the steam mill which burnt down in 1966 with its

grey silos on the waters edge.

|

|

Eling Experience has received a £1.7 million grant,

for capital works for the Tide Mill and the new

Heritage Centre and for ongoing work for the

community. It was particularly important to give a

good first impression upon entering the mill with

the new entrance. A large amount of work has been

undertaken to repair the machinery so that milling

can resume, and improved accessibility throughout

the mill enables all visitors to see everything

working.

The Heritage Centre has more information about the

mill with new displays in the Discovery Room, panels

with information, digital displays and some hands-on

activities. There is also a new café and extra

space for an activity room.

Outdoors the path to Goatee Beach has been widened

and levelled and a new footpath built right round

the millpond to create a circular walk accessible

for everyone including wheel-chair users. During

this time the team have worked with University

students, the New Forest Camera Club, local schools

and many other groups. They are making every effort

to involve local families.

|

Keith Andrews

These steps at the entrance to the mill convert into

a flat-floored lift for disabled access, thereby

saving space over the more usual separate stairs and

lift arrangement. |

|

The

Eling Experience was formally opened in April and

they now hope to recruit more volunteers for tour

guides, to help in the café, and to go out and about

to events in the locality. There is a regular

programme of events with family activities, talks,

science, walks and so on.

Ruth was asked how they would maintain funding for

the future and she said they had a business plan,

including a farm shop as well as income from the

café and activities.

|

Ruth Andrews

Eling Experience (above) occupies the ground

floor

of the remains of the steam mill. |

0275.jpg)

Tony Yoward collection |

| |

|

|

Eling Tide Mill Maltings - Robin Appel

HMG’s recent visit to Eling Experience for the AGM

in September was my first visit to the tide mill.

Arriving early, and spotting our chairman on the

quayside, I sought his guidance on car parking, and

he directed me to the public car park. Walking back

across the causeway I was immediately struck by an

architectural feature on the so called ‘old grain

store’ which immediately told me I was probably

looking at a former maltings!

|

|

|

Two windows which face out over Bartley Water (left)

feature distinctive square shaped vertical wooden

bars, set at 45 degrees to the facia, all just 4

inches apart, identical to the windows that surround

my historic maltings in Warminster (below left,

enlargement of window on right). Back in the

18th/19th century these wooden bars were imposed on

the whole UK malting industry by the Commissioners

of Excise who were responsible for regulating and

collecting the Malt Tax.

|

|

|

|

A duty on malt was first introduced in 1644 to meet

the growing costs of the Civil War, and over the

next 200 years the inelastic demand for beer made

the tax a soft target for government revenue in

times of need. In fact, right up to its repeal in

1880, it consistently generated in the order of 10%

of the total income from taxation. However, by the

end of the 18th century, the enormous dependence on

this one tax unleashed a complex web of legislation

to prevent fraud and evasion.

The tax was levied on volumes of malt produced, and

when the tax was hiked up in order to, for example,

build a new fleet of warships for the Napoleonic

Wars, maltsters struggled with the increase and

sought ways to avoid it.

No malt was allowed to be manufactured without

notifying the Excise Officers who had to measure the

volumes at 3 points in the production cycle: in the

steeping vessel, on the ‘couch’ ( the resting floor

for the ‘green malt’ between the steeping vessel and

the germination floors), and the germination floor

itself. The mean of the 3 volumes was that against

which the tax was levied.

|

|

|

One trick employed by maltsters seeking to reduce

their tax bill was to temporarily remove green malt

from the germination floors ahead of the Excise

Officer’s visit. The ventilation windows along the

germination floors were the easy point of exit, and

when it was established that this was a widespread

practice, the window bars became part of the strict

regulations, subject to onerous fines if not

complied with. |

|

When I went on to read the guide book Eling Tide

Mill, the history of a working mill (2010 edition) a

whole lot more evidence of malting was revealed. On

page 8 it records that in 1581 there were “two water

wheels … each driving two pairs of stones. One pair

ground wheat, while the other (pair) crushed barley

for malt making”. No, that is not quite right, ‘the

other’ crushed malt for brewing – you do not crush

barley before you make malt, but you do have to

crush malt before you can brew beer!

It is also important to point out at this stage that

the millstones would not have been interchangeable;

crushing malt for brewing should deliver a very

coarse grist compared to the fine grist that is

flour. Each set of stones would have been dressed

accordingly.

Then on page 10 the guide records “There was also a

kiln for drying germinating barley for malt

brewers”. From the earliest photograph of the mill

displayed in the Eling Experience exhibition (a

photograph taken from the northern bank of

Southampton Water), the kiln is very evident, albeit

inconveniently situated on the eastern elevation of

the mill, furthest from the germination floors. The

kilning of the green malt is the final critical

stage of the conversion of barley into malt. This

photograph also clearly shows horizontal shuttered

windows on the first floor of the maltings, all

three of which are hinged half open for the

important ventilation of the germination floor when

malting was in process.

So all this suggests that half of Eling Tide Mill’s

original production was devoted to milling wheat for

flour for baking, and the other half was making

barley malt, and crushing the malt ready for

brewing. We still crush malt for small brewers at

Warminster Maltings today. Then, it was something a

lot of smaller maltsters had to do, because many of

their customers for malt would have been households

brewing at home, and milling the malt could have

been beyond their ability. My home in Droxford,

part of which is the former village malthouse

(1672), declared in 1771 that it had a ‘Malt Kiln

and Malt Mill …’ the latter probably a small pair of

stones, gravity fed, and turned by hand. By

comparison, Eling’s investment in a dedicated

Poncelet wheel driving a pair of stones, might have

been viewed at the time as positively industrial,

feeding a strong demand for milled malt.

Reading on, it is not surprising then, that also on

page 10 of the guide, it records “In 1885, there was

even trade in beer supplied by Ashby’s Brewery of

Totton”. No doubt this would be beer coming back on

the horse and cart which had just delivered malt to

the brewery.

Back to page 4 of the guide, and it records that

“The mill building today was probably built in 1785

by John Chandler”, a prosperous and enterprising

corn merchant, and “the adjoining brick building,

once the grain store … was added early in the 19th

century”. Instead of ‘grain store’ we need to

substitute the word ‘maltings’. This was the period

when the Malt Tax regulations, which included the

vertical wooden bars in the ventilation windows,

became overzealous, causing maltsters to complain to

the Commissioners of Excise that they were being

harassed “with a vigour beyond the law”, and accused

of “an apparent delinquency, where none by fair

procedure would be found to exist!”.

So it would appear Eling Tide Mill was making and

milling malt for brewing for nearly 250 years, a

significant part of its recent history. This has

not been fully understood, and does not come over in

the Eling Experience. This is something that should

be rectified, because, although a flour mill and a

maltings on the same site under a single proprietor

was not uncommon in the 19th century, for example at

Burnham Overy Mill in Norfolk, a tide mill based

maltings is extremely rare, perhaps even more rare

than a tide mill which once milled, or even still

mills flour, such as Eling.

In HMG Newsletter 122, I recorded that on this

year’s summer visit Richard Ellis told us that mills

always ‘shook themselves to bits’. From my own

knowledge and experience, maltings were always

catching fire: the juxta-position of coal fired

kilns and dried barley and malt grains. Here at

Eling, the tide mill has continuously been ravaged

by floods. So no wonder John Chandler found himself

rebuilding it all at the turn of the 18th and 19th

centuries. That the structures have withstood any

further serious damage beyond neglect is

particularly fortunate, as they represent a unique

piece of history which from now on HMG will probably

have to share with the Brewery History Society.

|

|

|

|