|

|

|

Page 7 |

Newsletter 116, Spring 2017 © Hampshire Mills Group |

Quidhampton Mill, Overton

Richard Waldram

Part 1: History and Building

|

|

|

I have lived

in Overton for forty years and every time I

walked up Station Road I looked at

Quidhampton Mill and wondered vaguely what

was inside. Last August, I was updating the

information we have about Overton’s listed

buildings and asked the owners if I could

have a look inside the mill. Rather to my

surprise, my wish was granted. Being no

expert on water mills, I made sure I would

know a pit wheel from a wallower and read up

what was already known about this mill.

The mill is

one of four in Overton parish and lies only

a mile from the source of the River Test. At

the time of the Domesday Survey there were

two mills in the manor of Quidhampton. One

of them apparently soon fell into ruin, but

in the 14th century rolls of St Swithun's

there is frequent mention of the other, the

tithes of which were confirmed to the

almoner by John Syfrewast. This is probably

the present Quidhampton Mill.

At the

Hampshire Archives there are various leases

of Quidhampton manor and mill between 1669

and 1819 in which it is described as a

‘water grist mill or corn mill’ but no other

details are given. In 1763 John Webb,

yeoman and miller of Quidhampton, insured

his dwelling house for £50 and the utensils

and stock in his water corn mill (timber,

brick, and tiled) for £50. In 1819 the

Mill was in the possession of John Portal

who let it to Joseph Crimble. The Portal

family owned the paper making business at

Laverstoke and Bere Mills a few miles

downstream. In 1922, when electric power

was available, papermaking was transferred

to a factory next to Overton station just to

the north of Quidhampton Mill. Sometime

after 1921, a bucket wheel was put in the

mill to drive a water pump. It filled a

tank near the top of the hill to provide

running water to the newly built Station

Bungalows.

|

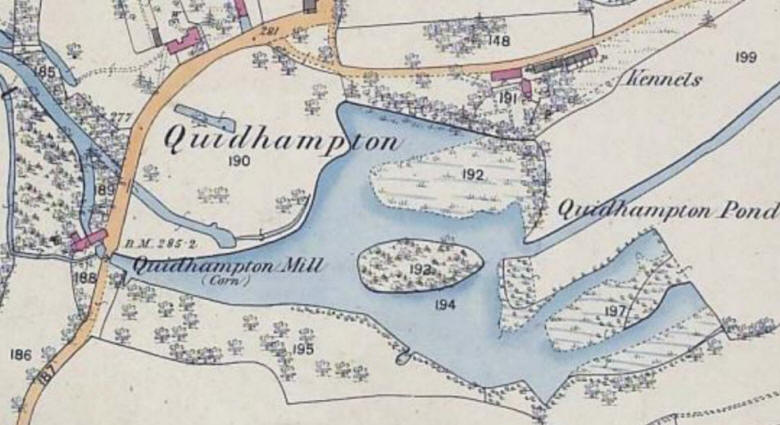

The extensive mill pond shown in the

Ordnance Survey map of 1873 was mainly

filled in sometime after 1961

|

|

Mills and Millers of Hampshire

records that John Loveless acquired the

lease in 1907 and held it until 1939 when

milling ceased. Quite by chance, I

discovered that this is not the whole story.

Just down Station Road lives a lady of 93

who grew up at the mill in the 1920s. John

Loveless was her grandfather who had

previously worked for the Crimbles at

Southington Mill to the west of Overton

village. Her father, also called John, was

born in 1893. He went off to the war in

1916 when he was 23 and served with the

Gloucester Regiment. He was badly wounded

in the head and leg and spent the next three

years in Roehampton Hospital. His daughter

said “he had a bad limp and was never the

same man again”. At some point,

however, he took over the lease of the mill.

It was probably just after 1923 when she

was born and her grandfather was 60.

She and her

sister played in the mill, whether it was

working or not, and it worked most days.

She remembers that it was noisy when the

wheel was running but it did not bother

them. Mostly they played ‘houses’ on the

top floor. They had a curtain across it and

this was their ‘den’. Catching rats around

the mill with their father was an endless

source of fun. They paddled in the mill

stream and the mill pond. Fishing for trout

was only for the gentry but the odd trout

did find its way to their table. She

thought they tasted of mud. They used an

eel trap, as all mills did, but she didn’t

like the taste of them either.

The farmers

brought their grain by horse and cart and

the sacks were taken in through the door on

the first floor by the road. The grain was

used to produce animal feed so the product

went back to the farmer who brought it.

She lived at the

mill till she married at the age of 20. She

does not know exactly why milling stopped or

when. When the war came, herds were reduced

to dairy cows only and arable production

increased to reduce dependence on imported

Canadian wheat. The ‘Ploughing-Up Campaign’

started in August 1939. Farmers were

instructed to plough two million acres of

grassland for the harvest of 1940 and grain

was reserved for human consumption. That

would have put John Loveless out of business

because he did not have the machinery for

removing impurities and making flour fit for

human consumption.

The mill was

listed Grade 2 in 1984 and is said to be a

17th century timber-framed

building with later alterations. The

miller’s house is 19th century.

In front of the mill is a footway above the

watercourses, formed by 3 brick arches

flanked by walling. |

|

Historic

England Archive No 1731_035 |

|

The views above

were taken in 1951. The left one shows the

timber framing and the access door to the

stone floor from the road. The massive

brick buttresses and the tie rods (below

left) must have been put in after this

date. It had been evident for some time

that the roof was in danger (photo below

right, Tony Morris

www.overtonpictures.com, taken in

2005). In 2007 the whole mill house was

encased in scaffolding and the roof covered

with tarpaulins for a couple of years. |

|

|

|

|

I found that

details of the planning application for

repairs were still on the Borough Council

website. There were three reasons for the

collapse. Two of the tie beams had been cut

resulting in outward thrust on the walls.

Some of the trusses had failed and the

purlins were not of adequate scantling. The

buttresses and tie rods (above) had failed

to solve the problem.

It was now

time to go and have a look. Knowing that

there was no electric power and very poor

daylight, I went armed with an extension

lead, a flood light and a torch. Inevitably

the extension lead was too short and I spent

a good deal of time stumbling around by

torch light amongst a lot of clutter trying

to get my bearings. But I soon realised

with great excitement that all the machinery

and equipment had been left exactly as it

was when the mill was closed. I also

realised I would need to come back, better

equipped to get photographs and survey the

whole building. This meant recruiting my

long-suffering wife to hold the end of a

tape measure. Fortunately, she likes this

kind of thing and in four hours the job was

done.

|

|

|

|

|

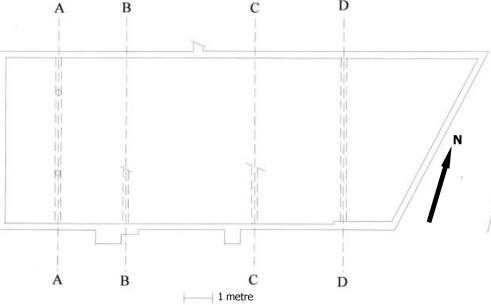

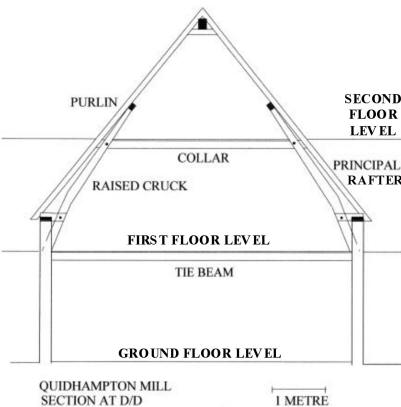

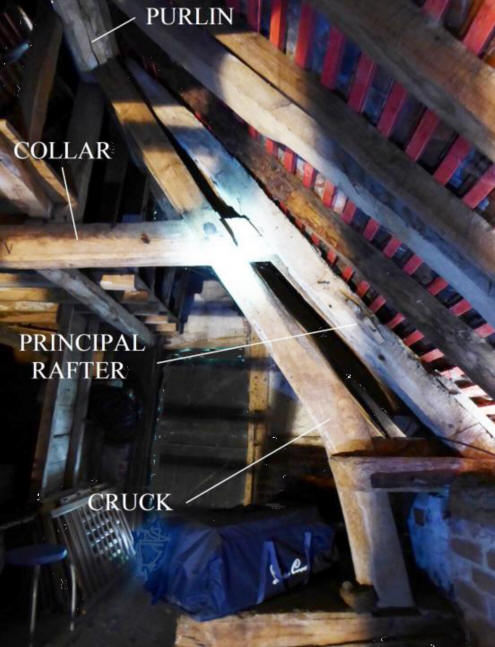

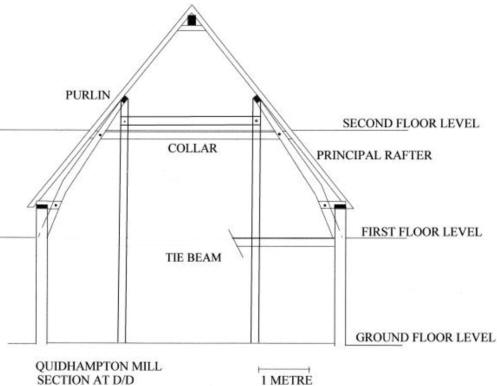

The building

is a four-bay structure, with three raised

cruck, arch-braced trusses at B, C, and D.

There is an

additional tie beam at A not associated with

a truss. Tie beams A and D are intact but

those at B and C have been cut, probably

when a new water wheel and machinery were

installed sometime in the 19th century. The

photograph left, taken at first floor level

looking east, shows the south end of truss D

which is the best preserved.

This form of

construction is unusual but is ideal for a

mill because it provides clear working space

on all three floors.

The

disadvantage is that it results in outward

thrust on the walls. If any tie beams are

cut, the whole structure depends on the

integrity of the collar, the cruck and the

wall. Eventually, four of the crucks

failed, the south wall began to lean, the

purlins sagged and the roof collapsed. New

purlins were put in supported by vertical

posts from ground level, leaving the

original roof structure otherwise intact.

This is how the building was saved.

|

|

|

The photo

above shows one of the new oak posts

supporting the purlins from ground level. |

|

Part 2: Mill

Machinery is in the next newsletter.

|

|

|

|